Numerical Simulation and Assessment of Meta Heuristic Optimization Based Multi Objective Dynamic Job Shop Scheduling System

Main Article Content

Abstract

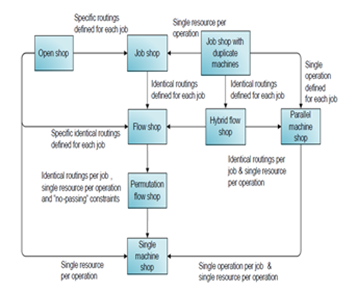

In today's world of manufacturing, cost reduction becomes one of the most important issues. A successful business needs to reduce its cost to be competitive. The programming of the machine is playing an important role in production planning and control as a tool to help manufacturers reduce their costs maximizing the use of their resources. The programming problem is not only limited to the programming of the machine, but also covers many other areas such such as computer and information technology and communication. From the definition, programming is an art that involves allocating, planning the allocation and utilization of resources to achieve a goal. The aim of the program is complete tasks in a reasonable amount of time. This reasonableness is a performance measure of how well the resources are allocated to tasks. Time or time-dependent functions are always it used as performance measures. The objectives of this research are to develop Intelligent Search Heuristic algorithms (ISHA) for equal and variable size sub lot for m machine flow shop problems, to Implement Particle Swarm Optimization algorithm (PSO) in matlab, to develop PSO based Optimization program for efficient job shop scheduling problem. The work also address solution to observe and verify results of PSO based Job Shop Scheduling with help of graft chart.

Article Details

This work is licensed under a Creative Commons Attribution-NoDerivatives 4.0 International License.

References

Bierwirth, C. A Generalized Permutation Approach to Job Shop Scheduling with Genetic Algorithms. OR Spektrum, 17:87-92. 1995.

Chang, Y. L, Sueyoshi, T. and Sullivan, R. S. Ranking Dispatching Rules by Data Envelopment Analysis in a Job- Shop Environment, IIE Transactions, 28(8): 631-642. 1996.

Davis, L., Job Shop Scheduling with Genetic Algorithms, Proceedings of the 1st International Conference on Genetic Algorithms, Pittsburgh, PA, 136-140. 1985.

Dimopoulos, C., Zalzala, A., Recent Developments in Evolutionary Computation for Manufacturing Optimization: Problems, Solutions, and Comparisons, Transactions on Evolutionary Computation, 4(2): 93-113. 2000.

Eberhard, R.C., and Kennedy, J., A New Optimizer Using Particle Swarm Theory, Proceedings. of the Sixth International Symposium on Micro Machine and Human Science, Nagoya, Japan, 39-43. 1995.

Fenton, P., Walsh, P., Improving the Performance of the Repeating Permutation Representation Using Morphogenic Computation and Generalized Modified Order Crossover, The 2005 IEEE Congress on Evolutionary Computation, 2: 1372-1379. 2005.

Giffler, B. and Thompson, G.L. Algorithms for Solving Production Scheduling Problems, Operations Research, 8(4): 487-503. 1960.

Goncalves, J. F, Mendes, J.J, and Resende, M.C.G., A Hybrid Algorithm for the Job Shop Scheduling Problem, AT&T Technical Labs Report TD-5EAL6J. 2002.

Jackson, J. R., Scheduling a Production Line to Minimize Maximum Tardiness, Research Report 43, Management Science Research Projects, University of California, Los Angeles, USA. 1955.

Jackson, J. R. Simulation Research on Job-Shop Production, Naval Research Logistics Quarterly, 4: 287-295. 1957.

Jain, A.S. and Meeran, S., A State-of-the-Art Review of Job-Shop Scheduling Techniques, European Journal of Operations Research, 113: 390-434. 1999.109

Lian, Z., Gu, X., Jiao, B., A Similar Particle Swarm Optimization Algorithm for Permutation Flowshop Scheduling to Minimize Makespan, Applied Mathematics and Computation, 2005.

Liu, J., Zhong, W., Jiao, L., A Multiagent Evolutionary Algorithm for Constraint Satisfaction Problems. IEEE Transactions on Systems, Man, and Cybernetics—Part B: Cybernetics, 36: (1): 54-73.2006.

Muth J.F., Thompson G.L., Industrial Scheduling, Englewood Cliffs, New Jersey, Prentice Hall. 1963.

Pang, W., Wang, K., Zhou, C., Dong, L., Liu, M., Zhang, H., Wang, J., Modified Particle Swarm Optimization Based on Space Transformation for Solving Traveling Salesman Problem. Proceedings of the Third International Conference on Machine Learning and Cybernetics, Shanghai, 4: 26-29. 2004.

Pirlot, M., General Local Search Methods, European Journal of Operational Research, 92: 493-511. 1996.

Rowe, A. J., Jackson, J. R., Research Problems in Production Routing and Scheduling, Journal of Industrial Engineering., 7: 116-121. 1956.

Smith, W. E., Various Optimizers for Single Stage Production, Naval Research Logistics Quarterly, 3: 59-66. 1956.

Song, M., Gu, G., Research on Particle Swarm Optimization: A Review, Proceedings of the 2004 Iternational Conference on Machine Learning and Cybernetics,4: 26-29. 2004.

Lawrence, S., Resource Constrained Project Scheduling: An Experimental Investigation of Heuristic Scheduling Techniques (Supplement), Graduate School Ind. Adm.. Pittsburgh, PA, Carnegie Mellon Univ., 1984.

Tasgetiren M. F., Yun-Chia Liang, Sevkli M., Gencyilmaz G., Particle Swarm Optimization Algorithm for Makespan and Maximum Lateness Minimization in Permutation Flowshop Problem, 4th International Symposium on Intelligent Manufacturing Systems, Sakarya, Turkey, 431-441. 2004.

Ta[getiren M. F., Sevkli M., Yun-Chia Liang, Gençy]lmaz G., Particle Swarm Optimization Algorithm for Single-machine Total Weighted Tardiness Problem, Congress on Evolutionary Computation, Portland, OR, 2: 19- 23. 2004.

Wang, K., Huang, L., Zhou, C., Pang, W., Particle Swarm Optimization for Traveling Salesman Problem. Proceedings of the Second International Conference on Machine Learning and Cybernetics, 3: 2-5. 2003.

Weijun, X., Zhiming, W., Wei, Z., and Genke, Y., A New Hybrid Optimization Algorithm for the Job Shop Scheduling Problem. Proceeding of the 204 American Control Conference. Boston, MA, 6: 5552-5557. 2004.

Xia, W., Wu, Z., An Effective Hybrid Optimization Approach for Multi-Objective Flexible Job-Shop Scheduling Problems. Computers and Industrial Engineering, 48: 409-425. 2005.

Engin and Alper Doyen, “A new approach to solve hybrid flow shop scheduling problems by artificial immune system”, Future generation computer systems, Vol. 20, pp. 1083- 1095, 2004.

Fantahun M. Defersha and Mingyuan Chen, “A hybrid genetic algorithm for flow shop lot streaming with setups and variable sub lots”, International Journal of Production Research, Vol. 48, No. 6, pp. 1705-1726, 2010.

Fantahun M. Defersha and Mingyuan Chen, “A genetic algorithm for one-job m-machine flow shop lot streaming with variable sub lots”, International Journal of Operational Research, Vol. 10, No.4, pp. 458 – 468, 2011.